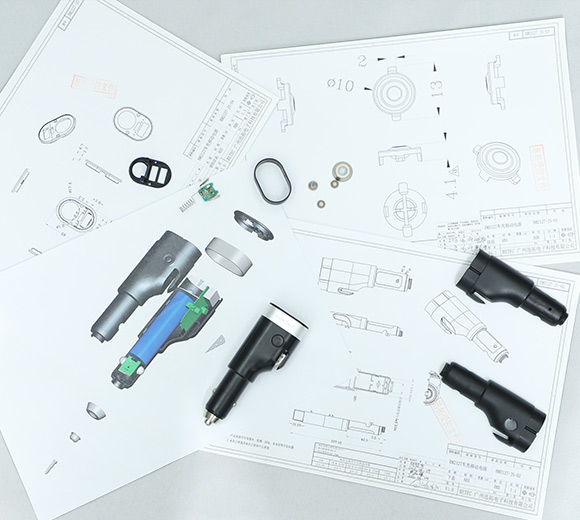

Plastic Injection

The plastic components we manufacture are strictly in compliance with the international export standards and environmental protection standards.

With the precise molding machine and delicate CAD drawings, the plastic components will be manufactured with accurate specifications.